Introduction

The medical industry is renowned for having a top-of-the-line, cutting-edge approach to developing new techniques. The credits directly go to the advanced technological solutions that have worked as a miracle for the user’s treatment.

3D printing industry trends have found their way into the healthcare industry due to their promising traits of converting the healthcare expert’s vision into reality.

The inclusion of 3D printing technology in healthcare industry’s arsenal has solicited their position in various ways by fortifying the resilience of healthcare professionals in delivering innovative treatment methods based on the severity of the diagnosed condition.

Prosthetics, novel surgical cutting and drill guides, and particular to patient reproductions of internal body parts, bones, and arteries are all made possible by 3D printing technology in the healthcare industry.

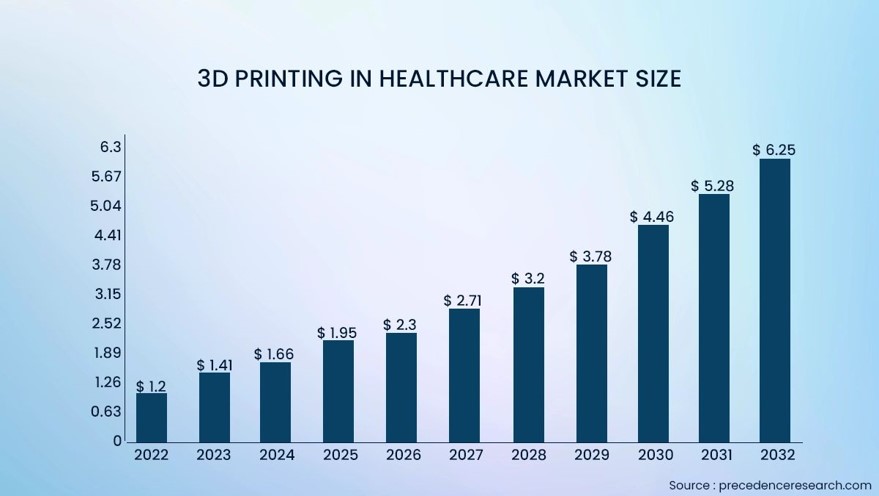

The total value of the global market for 3D printing in healthcare was pegged at USD 1.2 billion in 2022 and is projected to reach USD 6.25 billion by 2032, gaining at a projected CAGR of 18% from 2023 to 2032.

The state-of-the-art development has been proven to be affordable, delivered durable, lighter products for the users, and has shorted lead times in the healthcare sector. Every individual’s needs vary and can be met with customizable prosthetics.

As a result, medical practitioners are in the optimum condition to under the user and even the individual to develop the connection for the things that are tailored based on their anatomy.

Let us understand in detail what precisely is 3D printing technology in healthcare industry and its applications.

What is 3D Printing?

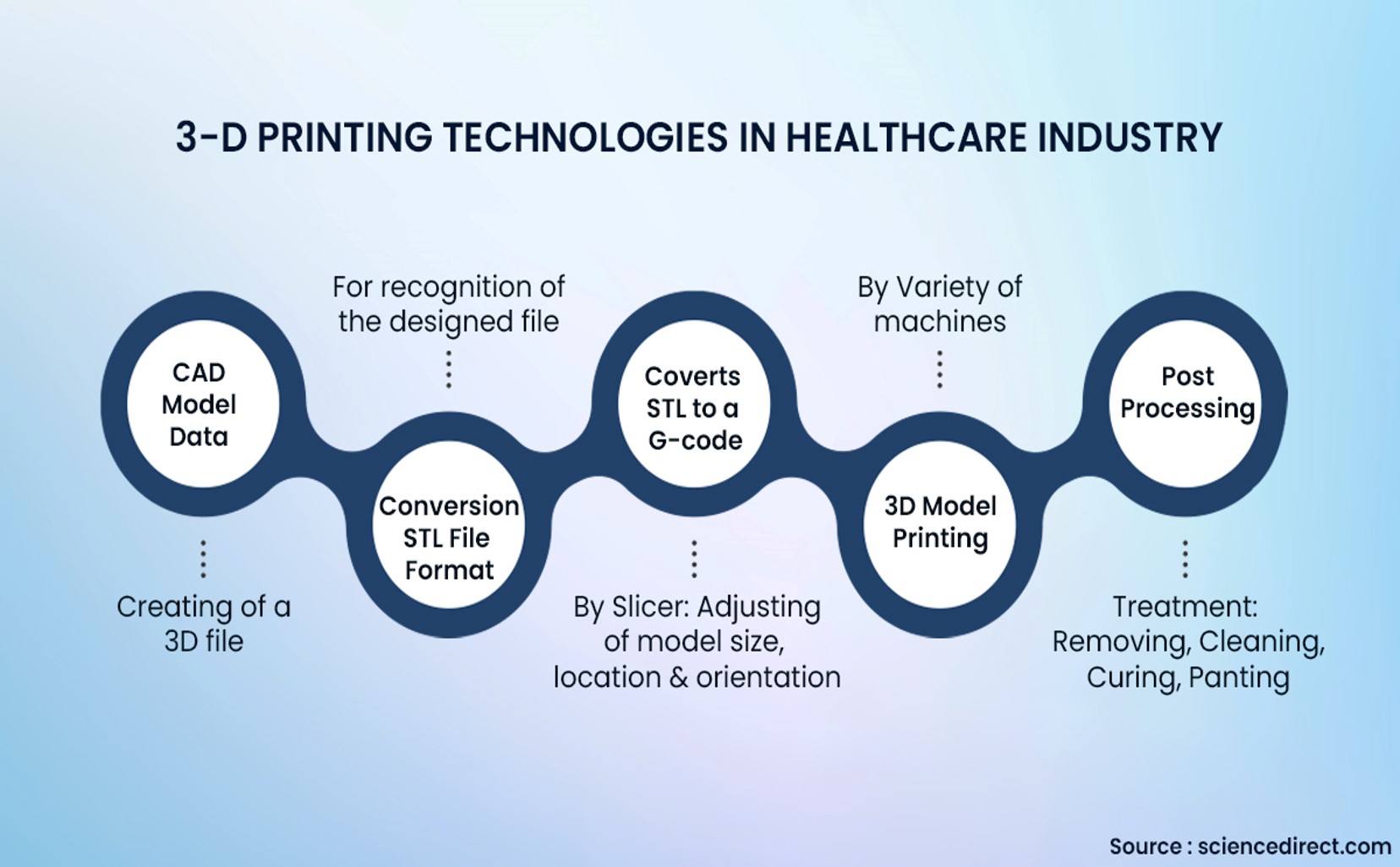

The 3D printing is developed from a CAD model curated in digital mode. The printing is performed using an array of techniques in which the components, such as polymers, powered grains, and liquids, are blended together and transferred for the solidification process under direct computerized vigilance.

Benefits of 3D Printing Technology in Healthcare Industry

We could never have imagined the immense potential of 3D printing in the healthcare sector. Depending on the circumstances, 3D printing offers healthcare professionals several advantages, including the following:

- Cost Efficient

- It can reduce the utilization of ineffective supplies, and 3D printing can save money on manufacturing funds allocation. This can be effective for traditionally smaller implantations or prostheses to revive damaged spinal defects, dental implantations, and more.

- The 3-D printing technology can design any object at a fraction of the reasonable cost at a practical market value.

- Increase in Productivity & Workflow

- 3-D printing has been witnessed to develop prostheses and implantation at a faster pace as the requirements can be met within a matter of hours.

- It curbs the traditional long manufacturing cycle process by discarding milling and forming processes used earlier.

- Precision and Reliability

- Digital reports (Data) are involved in developing the 3D-printed prostheses. The curated reports are further diagnosed by the seamlessly integrated technology, which lowers the area of scope for misinterpretation of the data.

- Fusing AI into the 3D printing devices and systems can filter out and plaster errors quickly, enabling healthcare professionals to make an accurate call.

- Customized Approach

- The advancement of 3D printing technology in the healthcare industry has equipped healthcare experts for the formation and designing of medical supplies and types of pieces of equipment.

- The healthcare practitioners and surgeons can now perform surgeries more efficiently in the operating theatre using innovatively designed prosthetics.

- Collaborative Nature

- The interchange of data amongst academics has encouraged the sharing data files for 3D printing. Researchers and scholars from the healthcare industry extract the STL files from the available liberated database rather than from a sophisticated computer environment.

- The integration of the 3D printer has enabled them to design and develop a precise copy of the medical model from any part of the globe.

Challenges witnessed due to 3-D printing in healthcare industry

The healthcare technology manufacturers are adaptive to the latest advancements in 3-D printing. Alongside the brightly shinning benefits, there are a few dark drawbacks which you should be aware of:

Regulatory Hurdles

- One of the strenuous hurdles is the way to navigate the regulatory environment. This not only requires adequate money and stressing hours for certifying if the designed 3D printed prosthesis follows up with safety and standards set by the FDA authorities.

- Due to the no effective clearance and criteria for 3D printing, it creates complexity among the manufacturers to work efficiently and follow the ideal industry-standard processes.

Raw Material Supply & Quality

- Opting out of the precise raw materials for 3D printing in the healthcare industry is obligatory. To preclude any adverse reaction or failure during implantation can be a serious concern.

- The manufacturers must rely on biocompatible materials which meet the requirements. Quality control in every stage of the manufacturing of the prosthesis is a must for the prevention of any occurred anomalies or malfunctions during the developing stages.

Data Security

- 3D printing primarily requires the data of the individual, which includes diagnostic scanned reports. Safeguarding this critical information from cyber hazards is a hardship and a must for every healthcare.

- These organizations mandatorily must instate in stalwart cyber security solutions available in the market that comply with data regulations such as HIPPA.

Affordability of the Technology

- The maiden investment in acquiring these high-tech 3D printers requires a more significant investment, which can act as a hindrance for the smaller established healthcare institutes, as this has the potency to lower the excessive wastage of materials during the preparation of the required products.

- For a persuasive understanding of the potential that the technology contains, every health organization must get access to develop a better understanding on this.

Ethical Challenges

- 3D printing technology has imbibed the skills to create a replica of any medical prostheses or even the internal tissue of an individual, which has led to heated tension for various legal issues and moral ethics.

- The frequently debated issues are direct accountability of the malfunctioning devices, medical structure model, and exploitation of the advanced technology, which needs to be sorted meticulously, and it is possible only with the predominant regulatory frameworks and norms.

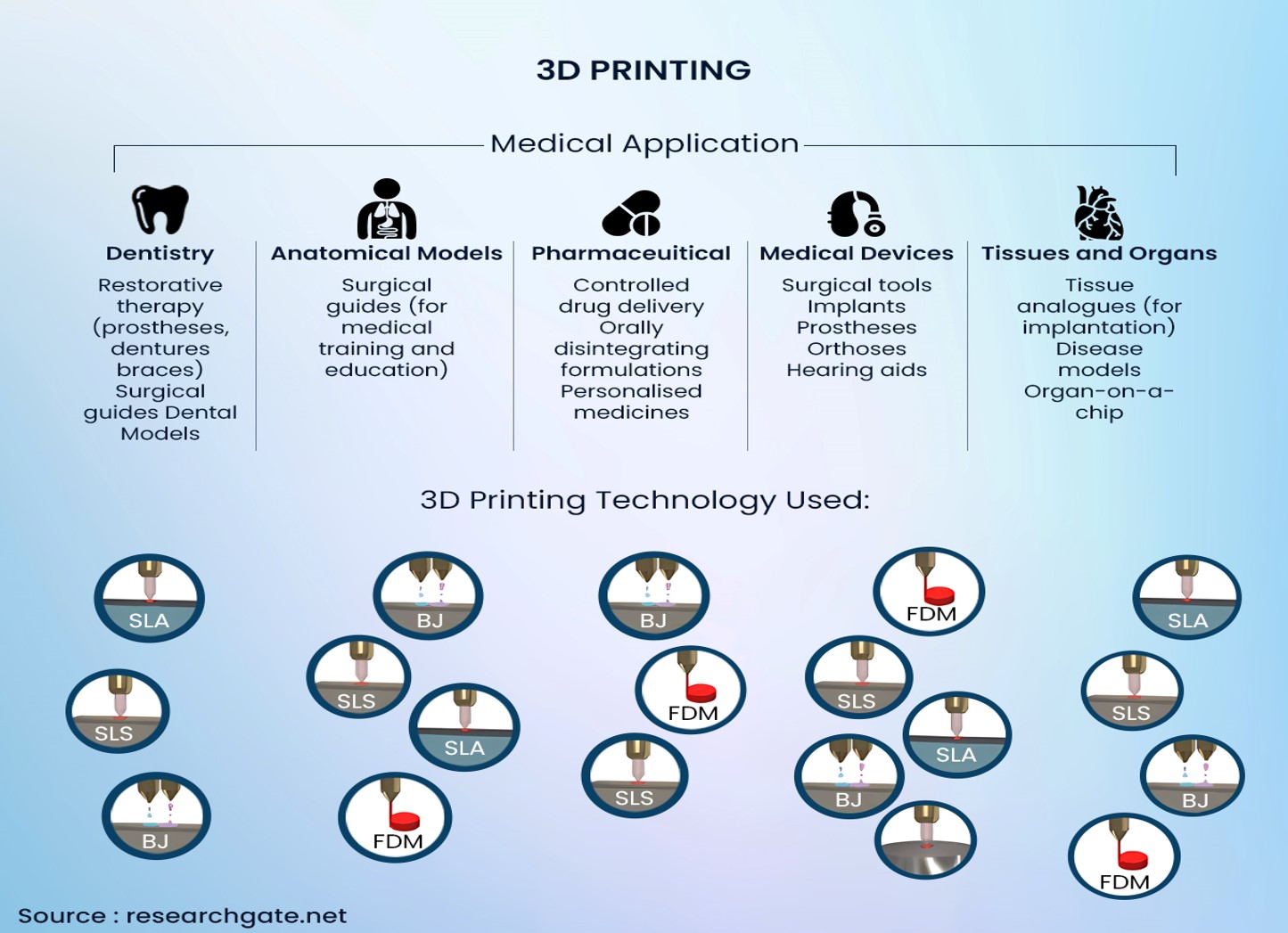

Applications of 3-D Printing Technologies in Healthcare Industry

3-D printing technologies have obtained the trust and attention of significant numbers of healthcare experts. It is benevolent in various areas of the healthcare industry; credit goes to the range of versatility that it has displayed. Let us review the various applications of 3D printing in the healthcare industry:

Yielding Cost-Effective Prosthetics

- Individuals who are diagnosed with any significant hereditary defects are losing off their locomotory limbs and require access to a set of customized prosthetics. However, it can be exorbitant on the set budget, making them unaffordable for various individuals.

- The cutting-edge technology of 3-D printing in the modern days provides an economical-friendly alternative. These custom-made prosthetic limbs can be designed and formed within the slash of the cost, which is involved in traditionally developed prosthetics.

- The ability to design advanced prosthetics and orthotic devices that are specifically tailored to the patient’s anatomy uniquely via 3D printing annihilates the existence of other manufacturers to expand its suitability.

Surgical Tools Advancement

- Surgical equipment is absolutely essential for healthcare practitioners to perform surgeries. Most often, the metals that are utilized for the formation of this medical equipment are made out of Aluminum or titanium, which are ideal for their characteristics and durability.

- With the inclusion of 3D printing, the experts can produce equipment that can simulate the unique anatomy of the users. The process involved in installation for the functional treatment, which includes prostheses and structuring plates, has improved the overall outcome postoperatively.

- It is possible to form the equipment using FDM 3D printing technology, which is highly cost-effective.

Replication of the Human Anatomies

- One of the significant applications of the 3-D printing in the healthcare industry is anatomical replications. Physicians and practitioners are operating using 3D printed diagnosed data, which elucidate the option for the treatment, pre-operational surgical practice prior to performing in real-time.

- These 3D printed models assist clinicians in comprehending the entirety of the diagnosis, which can be challenging to dissect for an effective diagnostic understanding.

- This technique can further be incorporated as a medium for informing the working peers and also the individual’s loved ones about any upcoming medical procedure while keeping your co-workers updated about the stages involved during the surgical treatment.

- Numerous surgeons ideally run a set of sample practices prior to conducting critical surgeries using various simulators and models, which can be replaced using the 3-D printed model. This can become the guiding medium that can be utilized by budding healthcare practitioners.

- This can act as sample practice for the surgeons to understand the paraphernalia and develop the preparedness for the forthcoming operating scenarios of various internal structures of the individual’s anatomy. FDM is renowned for curating geometrical surgical models, which comprise significant intriguing details.

Hearing Aid

Hearing aids have been ranked as the best outcome for eliminating hearing difficulties with the advancement of Additive manufacturing (AM). It is responsible for the production of almost 97% of various hearing aids that are developed across the globe.

AM, has lowered the cost of production when compared to the conventional hearing aids which were designed. Likewise, the ability to develop surfacing textures that are intricate has decreased the poor fit return rates from 40% to now 10%.

Future Trends in 3D printing technology in healthcare industry

The establishment of 3D printing has been a promising advancement in recent years. The primary aim of printing 3D anatomy organs for successful transplantations will allow the inception of homologous organs, which are designed using the individual’s cells; this intricate cytoarchitecture of organs has made the giant 3D printing bite dust.

Medical organizations are advancing the modification of the earlier curated products for the sustainability of the printing style in 3D, and extensive research on expanding the range of materials that could be utilized for the formation of 3D printing for the improvement of overall designing efficiency and the required high speed on 3D printing.

Final words

3D printing tools have emerged as sensational advancements in the healthcare industry. The printing has stood against the challenges but needs a reinforcing touch for the rectification of the ongoing challenges which has been witnessed globally. It will be exciting to see the potential that 3D printing is containing for healthcare experts. Keep an eye on one of the fastest-growing prospects in the healthcare sector; 3D printing will rise and design the future of the healthcare industry.

Facebook Comments